-

Product

IntroductionProduct Introduction

-

Technology

IntroductionTechnology Introduction

-

Sustainable

ManagementSustainable Management

-

Company

IntroductionCompany Introduction

-

Customer

SupportCustomer Support

Technology Introduction

HOME Technology Introduction Metallization

Metallization

Based on the market-proven thin film metallization know-how and efficient pin-hole defect minimization skills accumulated for the past 30 years, Seoil now aims to be the world's best film solution provider. With its advanced vacuum metalizing technology, Seoil produces eco-friendly materials required by the customers. We pursue being a company that not only satisfies its customers but also protects the environment for generations to come.

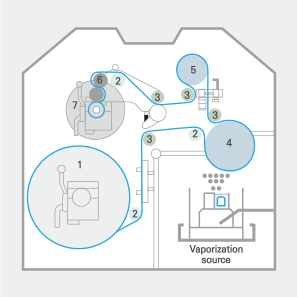

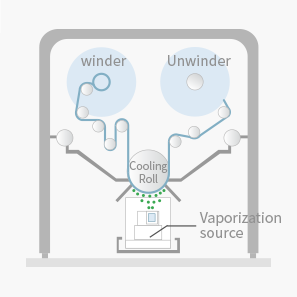

Thermal Evaporator

It is a metallization technology that forms a thin film using aluminum vaporized by applying heat in a high vacuum. It is possible to add various functions of the film-forming material to the substrate.

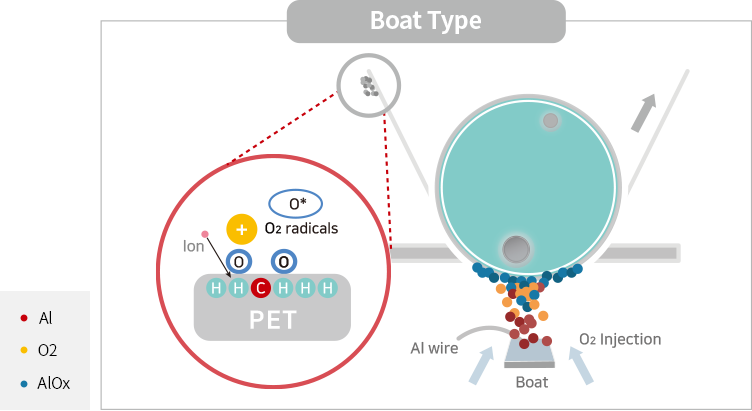

Resistor (Boat) Heating Evaporation Technology

It is a deposition technology that heats a resistor (boat) by flowing an electric current in a high vacuum state and supplies a film-forming (metal) material to the heated boat in order to form a thin film with the vaporized film-forming material. Various properties of the film-forming material can be added to the substrate.

Crucible-type Evaporator

This deposition technology vaporizes the film-forming (metal) material in the crucible through high-frequency induction heating in a high vacuum statue, and forms a thin film on the substrate. A range of properties of the film-forming material can be added to the substrate.

Aluminum Oxide (AIOx) Thermal Evaporator

Introduction of AIOx Thermal Evaporator

Seoil has continued with its efforts to advance the Al vacuum metallization technology for 30 years. Now Seoil boasts of its fully-secured mass production technology of large-area, superior-uniform AIOx that features high barrier, high transmittance, and high quality.

AIOx High Barrier Film Technology

The plasma pretreatment in the vacuum evaporator forms polar functional groups such as OH- and H+ on the film surface, strengthens the bonding force with Al³+ and O²-, and thereby improves adhesion.

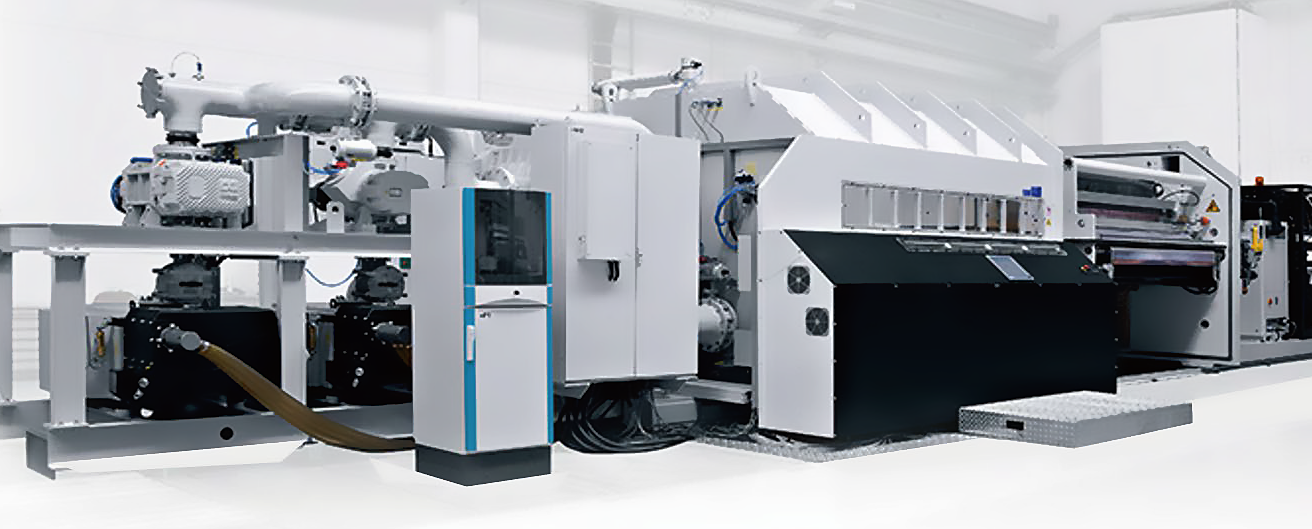

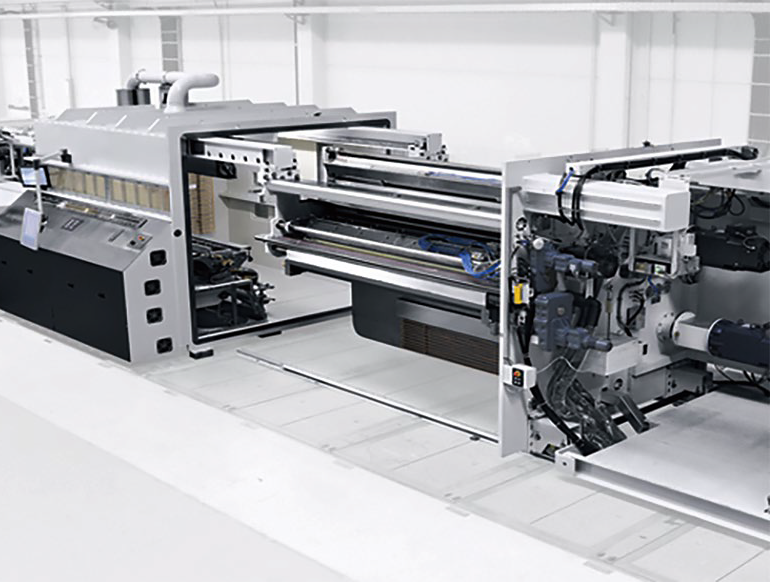

Metallization Facility Specification

| Evaporator No | ML-1 | ML-2 | ML-3 | ML-4 | ML-5 |

|---|---|---|---|---|---|

| Basic Material Handled | PET, A-PET, OPP, CPP, PLA Paper, Etc. | ||||

| Thickness of the Basic Material | 12 ~ 250㎛ | 12 ~ 250㎛ | 12 ~ 38㎛ | 12 ~ 36㎛ | 8 ~ 25㎛ |

| Metallization Material | Aluminum(Al) | Aluminum(Al) | Aluminum(Al) | Aluminum(Al) | Aluminum Oxide(AlOx) |

| Metallization Width | 800 ~ 1650mm | 1000 ~ 2250mm | 1650 ~ 2500mm | 1000 ~ 2450mm | 1200 ~ 2450mm |

| Product | Packing, Window, Outer Packing, Label, Electric and Electronic Parts, Metallic Yarn, [Display, Medical, Solar Cell](ML-5 only), Etc. | ||||

| Plasma Function | None | None | Both sides (Ion Bombard) | Single side | Single side |