-

Product

IntroductionProduct Introduction

-

Technology

IntroductionTechnology Introduction

-

Sustainable

ManagementSustainable Management

-

Company

IntroductionCompany Introduction

-

Customer

SupportCustomer Support

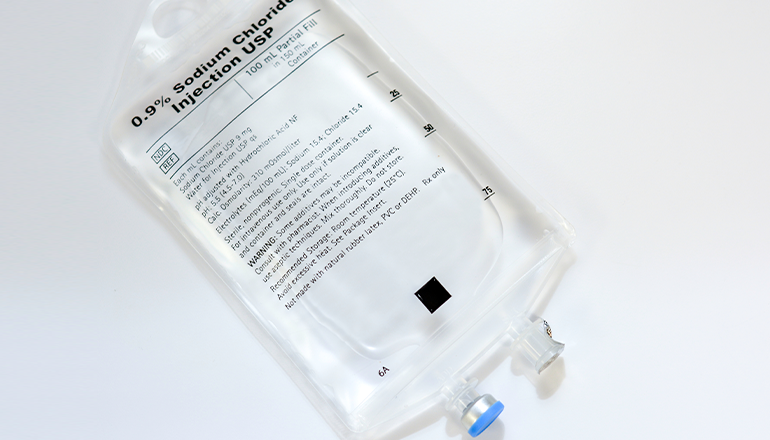

For MedicalALO SKY - M

Product Introduction

Medical supplies can be easily deteriorated when they are exposed to moisture and oxygen (due to moisture absorption or oxidation), and their concentration can be changed as well when water evaporates from the solvent. For this reason, the barrier function of pharmaceutical packaging is critical in order to protect and maintain their intended medical functions.

The excellent barrier properties of the transparent barrier film incredibly enhances the storage stability of the content.

Product Characteristics

-

Moisture Barrier

-

High Permeability

-

Stickiness

Product Properties

| Property | Spec |

|---|---|

| WVTR (g/m²day) | 0.02 ~ 0.05 |

| OTR (cc/m²day) | 0.02 ~ 0.05 |

| VLT (%) | 88 or more |

| Haze | 2.5 or less |

| Wettability (mN/m) | 50 or more |

※ As the base film is selected according to the intended application, the physical properties may vary.